- Home

- Products

- Worm Gear Shaft Milling Machine

- Machine Speed and Effi. Comparison

Machine Speed and Effi. Comparison

Machine Speed and Effi. Comparison

Performance Comparison:

| Country | Speed |

|---|---|

| Shaft Modular | |

| RGL | 130 seconds |

| Germany | 646 seconds |

| Japan | 750 seconds |

*The information from RGL existing equipments.

Worm Teeth Cutting Test :

| Worm Material : | S45C |

Hexagonal part machining |

|---|---|---|

| Module : | M3 | |

| Length : | 50mm | |

| Accuracy : | 5µm / 100mm | |

| Time : | Shortened by 70% |

Surpasses the Speed and Accuracy of Whirl Wind Type Milling Machine

worm profileApplicable Jobs

Worm / Dual-lead Worm / Variable-lead Worm / Tapered Worm / Lead Screw /

Spline Shaft with 6,8 or 10 Grooves/ Emove Sharp Corners on Thread / keyway.

Spline Shaft Work Pice

Spline Shaft Work Pice Work Pice

Work Pice

(To Match With Bevel Gear) Worm Shaft

Worm Shaft Work Pice

Work Pice DUAL-LEAD Work Piece

DUAL-LEAD Work Piece Hexagonal part machining

Hexagonal part machining Cavex

Cavex Grinding Wheel Machining

Grinding Wheel Machining Integral forming blade feed rod

Integral forming blade feed rod M4-SCM440

M4-SCM440 M5-S45C

M5-S45C

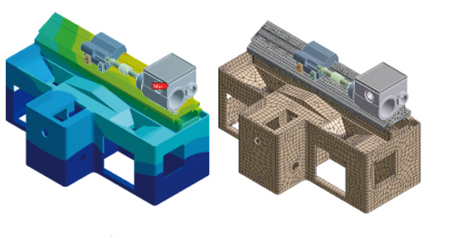

Optimized Machine Structure High Rigidity !

Deformation Free

The structural parts of the machine, such as the base and saddle, are analyzed by using the advanced Finite element Analysis software. When the structural parts are subjected to a maximum load, there is almost no deformation on the base and a minimum deformation of less than 10µm on the saddle. This gives a proof for the unmatched structural rigidity of DS-1000.

Machining Applications:

- Thread Milling (Single Lead, Dual Lead, Taper, Hypoid Gear And Neiman Type Machining)

- Spline Shaft Machining.

- Grinding Wheel Slotting.

- For Removing Sharp Corners on the Threads.(DS-1000HZ only)

- Applicable for Machining Keyways.(DS-1000HZ only)

- Polygon Milling Operations.(DS-1000HZ only)

In the fiercely competitive manufacturing market, our newly launched multi-functional screw machining center significantly enhances operational efficiency. Adhering to lean production principles, the machine is designed to be simple and efficient, saving time, effort, electricity, money, and space.

Initially designed to optimize processes and multifunctionality, it has been found through practical operation to effectively reduce the waste of manpower and materials, making it an ideal choice for those seeking high efficiency and cost-effectiveness.